Global and European Magnesium Oxide Market Outlook 2025 to 2035

The magnesium oxide market is projected to grow from USD 4.6 billion in 2025 to USD 8.7 billion by 2035, at a CAGR of 6.6%.

LONDON, LONDON, UNITED KINGDOM, November 17, 2025 /EINPresswire.com/ -- The global magnesium oxide (MgO) market is poised for a decade of steady acceleration, with Future Market Insights (FMI) projecting growth from USD 4.6 billion in 2025 to USD 8.7 billion by 2035, registering a 6.6% CAGR. Supported by rising steel production, environmental compliance requirements, and advanced applications across electronics and energy storage, the industry is transitioning from traditional refractory-driven consumption to broader, innovation-led demand.

According to FMI, the 2025–2030 period marks an acceleration phase driven by robust uptake in refractories, cement, agriculture, and wastewater treatment. Between 2030 and 2035, growth stabilizes as global supply chains mature and high-purity MgO grades for electronics, batteries, and medical uses balance deceleration in conventional sectors.

Subscribe for Year-Round Insights → Stay ahead with quarterly and annual data updates: https://www.futuremarketinsights.com/reports/sample/rep-gb-1622

Global Demand Expands with Strong Regional Momentum

FMI confirms that APAC, North America, Europe, and the Middle East (notably Saudi Arabia) will remain pivotal demand centers:

- APAC leads global volume growth, driven by steel capacity expansion in India and China and high-specification material requirements in South Korea.

- Europe demonstrates strong specialty refractory and environmental treatment demand.

- The USA expands its MgO usage through rising electric arc furnace (EAF) steelmaking and stricter environmental regulations.

- Saudi Arabia accelerates adoption of MgO in industrial processing, wastewater treatment, and construction materials under rapid industrialization initiatives.

India remains the fastest-growing national market with a 9.1% CAGR, followed by China at 8.4%, reflecting the region’s dominance in steel, cement, and refractory applications.

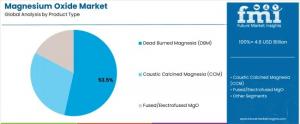

Dead Burned Magnesia Continues to Lead Product Demand

In 2025, dead burned magnesia (DBM) is projected to hold a 53.5% market share, solidifying its role as the industry’s cornerstone for high-temperature processes. DBM’s exceptional density, corrosion resistance, and stability above 2000°C make it indispensable for basic oxygen furnaces, electric arc furnaces, cement kilns, and glass melting tanks.

Its performance-critical characteristics directly address industrial demands for:

- Longer furnace campaign life

- Reduced refractory maintenance

- Stable performance under aggressive slag environments

Iron & Steel Industry Holds 44% Market Share in 2025

The iron & steel segment remains the largest end-use industry, commanding 44% of global MgO consumption in 2025. The shift from blast furnace to EAF steelmaking is increasing refractories turnover, reinforcing long-term demand for premium-grade MgO products.

Other key downstream sectors include:

- Cement & glass (23%)

- Non-ferrous metallurgy (10%)

- Agriculture & feed (9%)

- Environmental services (8%)

- Chemicals & pharma (6%)

Key Drivers Supporting Market Expansion

1. Growing Global Steel Production

Rising steel output—especially via EAF routes—pushes demand for MgO refractory linings capable of resisting extreme thermal cycling and corrosive slags.

2. Environmental Compliance & Pollution Control

Industries worldwide are utilizing MgO in:

- Flue gas desulfurization (FGD)

- Industrial wastewater treatment

- Acid neutralization systems

The material’s cost-effective neutralization capabilities support regulatory compliance in power generation, municipal water treatment, and industrial operations.

3. High-Purity and Specialty Grade Innovations

Emerging applications include:

- Electronics glass manufacturing

- Lithium-ion battery cathode materials

- Pharmaceutical excipients

- Advanced ceramics and specialty chemicals

FMI highlights that high-purity MgO demand will significantly contribute to market value through 2035.

Gain complete access to the report for extensive coverage of market forecasts, competitive benchmarking, and evolving industry trends! https://www.futuremarketinsights.com/checkout/1622

Regional Highlights

India (9.1% CAGR)

Driven by steel capacity additions, cement upgrades, and expansion of livestock nutrition requiring feed-grade MgO.

China (8.4% CAGR)

Sustained by its position as the largest steel producer and a major fused magnesia manufacturing hub.

United States (4.5% CAGR)

Growth fueled by EAF steelmaking and environmental treatment applications.

South Korea (6.6% CAGR)

Demand for ultra-high purity MgO accelerates in electronics glass and battery material industries.

Europe (Overall CAGR 4.5%)

Germany, France, Italy, Spain, and the U.K. remain key consumers across refractories, cement, glass, and environmental technologies.

Saudi Arabia: Rising Demand Under Industrial Transformation

FMI identifies Saudi Arabia as a strategically important market, supported by:

- Expanding cement and steel applications

- Environmental treatment initiatives

- Construction sector modernization utilizing magnesia board systems

The region’s industrial diversification efforts will increase consumption of DBM and CCM grades through 2035.

Market Opportunity Landscape

FMI outlines a robust opportunity matrix across production, technology, and regulatory dimensions:

- Manufacturers are investing in energy-efficient calcination technologies to reduce emissions.

- Environmental service providers are optimizing MgO for higher treatment efficiency.

- Steel producers are adopting data-driven refractory management to extend furnace campaign life.

- Investors are backing capacity expansions in high-growth markets including India, Southeast Asia, and the Middle East.

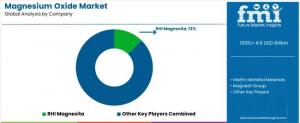

Competitive Environment

The market remains moderately consolidated, with leading global producers expanding technological capabilities to deliver consistent, high-performance MgO products. Strategic initiatives focus on:

- Advanced calcination systems

- High-purity grade development

- Sustainable mining and processing

- Enhanced quality certification frameworks

FMI’s analysis underscores that companies prioritizing purity innovation, energy efficiency, and regional capacity strengthening will secure long-term competitive advantages.

Exploring Insights Across Emerging Global Markets:

Bioplastic and Biopolymer Market: https://www.futuremarketinsights.com/reports/bioplastic-and-biopolymer-market

Aqueous-based Metal Cleaner Market: https://www.futuremarketinsights.com/reports/aqueous-based-metal-cleaner-market

Blow Molding Resin Market: https://www.futuremarketinsights.com/reports/blow-molding-resin-market

Cashew Nutshell Liquid Market: https://www.futuremarketinsights.com/reports/cashew-nutshell-liquid-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Why Choose FMI: Empowering Decisions that Drive Real-World Outcomes: https://www.futuremarketinsights.com/why-fmi

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.