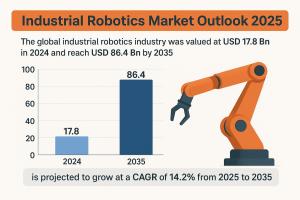

Industrial Robotics Market Set for Rapid Growth, Expanding from USD 17.8 Bn in 2024 to USD 86.4 Bn by 2035 | TMR

Government support for smart manufacturing and Industry 4.0 are activating investments in robotics infrastructure.

Industrial Robotics Industry Forecast: Strong 14.2% CAGR Expected Between 2025 and 2035”

WILMINGTON, DE, UNITED STATES, October 7, 2025 /EINPresswire.com/ -- The global industrial robotics market was valued at USD 17.8 billion in 2024 and is projected to reach USD 86.4 billion by 2035, growing at a robust CAGR of 14.2% from 2025 to 2035. This growth is driven by the rising adoption of automation across manufacturing sectors, advancements in AI and machine learning, and increasing demand for precision and efficiency in industrial operations.— Transparency Market Research Inc.

The industrial robotics market’s growth is driven by technological advancements, governments’ initiatives, and addressing labor shortage problems. With their versatility and flexibility, industrial robots have the advantage of being easily deployable to sites where deploying a specialized machine is not ideal or where large-scale facility renovation is difficult.

Industrial robotics implies a programmable device that performs work in manufacturing and industrial settings. These robotic devices intend to perform tasks that are complex, hazardous, or repetitive at a high level of precision, precision, and speed.

Dive Deeper into Data: Get Your In-Depth Sample Now! https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=3187

Common tasks for industrial robots include welding, material handling, assembly, painting, packaging, and inspection of quality. Industrial robots can either be fixed or mobile in location. Collaborative robots, which are robots that can physically work with human workers without safety barriers, are one of the recent developments in industrial robotics. Artificial intelligence (AI), machine vision, and the Internet of Things (IoT) have enhanced the potential use of industrial robots, along with flexibility and functionality.

The growth of the industrial robotics market is driven by an increased demand for automation across multiple industries such as automotive, electronics, pharmaceuticals, food & beverages, and logistics. Labor costs have continued to rise, along with the even greater challenge of finding good labor.

Market Segmentation

By Service Type

Installation & Integration: System design and on-site deployment by specialists.

Maintenance & Support: Preventive/predictive maintenance, spare parts, remote diagnostics.

Training & Consulting: Workforce upskilling and process re-engineering.

Robotics-as-a-Service (RaaS): Subscription and pay-per-use models lowering adoption barriers.

By Sourcing Type

In-house production: Large OEMs building proprietary automation solutions.

Third-party suppliers/integrators: Robotics OEMs, specialized system integrators, and VARs offering turnkey solutions.

Contract manufacturing/service providers: Outsourced automation services for SMBs.

By Application

Welding & Joining

Material Handling & Palletizing

Assembly & Machine Tending

Painting & Surface Finishing

Inspection & Quality Control

Packaging & Palletizing

Other (cutting, dispensing, lab automation)

By Industry Vertical

Automotive & Auto Components — historically the largest adopter.

Electronics & Semiconductors — high precision, micro-assembly demand.

Food & Beverage and Consumer Goods — flexible packaging and hygiene-compliant systems.

Pharmaceuticals & Medical Devices — sterile handling and traceability.

Metals & Machinery

Logistics & Warehousing — rise of fulfillment automation.

Others: Chemicals, textiles, plastics.

By Region

Asia Pacific — leading market share, driven by China, Japan, South Korea and growing adoption in Southeast Asia and India.

North America — strong demand from automotive, electronics, and logistics; emphasis on smart factories.

Europe — advanced manufacturing hubs, strong adoption of collaborative robots and Industry 4.0 initiatives.

Rest of World — emerging adoption across Latin America, Middle East & Africa.

Regional Analysis

Asia Pacific will remain the growth engine due to large manufacturing bases and government support for automation. North America and Europe will show steady growth, fueled by reshoring trends, advanced electronics manufacturing, and logistics automation. Emerging markets will see faster relative growth from a low base as cost-effective RaaS and modular solutions reduce barriers.

Market Drivers

Labor shortages and rising wages: Push manufacturers to automate repetitive and hazardous tasks.

Demand for higher throughput and consistent quality: Robotics reduces defects and variation.

Technological advances: AI, machine vision, force sensing, and better end-effectors enable new use cases.

Flexible automation needs: Shorter product life cycles require reconfigurable robotic systems.

Service and software monetization: Growth in RaaS, connectivity, and predictive maintenance services increases lifetime value per robot.

Logistics & e-commerce growth: High demand for picking, sorting, and fulfillment automation.

Market Challenges

High upfront capital expenditure for advanced, highly-capable systems (though RaaS mitigates this).

Integration complexity: Legacy lines and mixed vendor equipment create systems-integration hurdles.

Workforce skills gap: Need for technicians skilled in robotics, PLCs, vision systems and data analytics.

Cybersecurity and connectivity risks: More connected robots mean heightened security needs.

Regulatory and safety compliance: Standards and certification for human-robot collaboration must be met.

Supply-chain constraints: Component shortages or geopolitical issues can constrain deployments.

Market Trends (2025–2035)

Collaborative Robots (cobots) proliferation: Safer, easy-to-program cobots expand usage in SMEs.

AI-powered autonomy: Machine learning enhances path planning, quality inspection, and adaptive control.

Edge computing + 5G: Low-latency control and fleet orchestration become commonplace in smart factories.

Modular, plug-and-play systems: Faster deployment cycles and reconfiguration capabilities.

Vertical-specific solutions: Pre-configured robotic cells for food, pharma, electronics and logistics reduce time-to-value.

SaaS for robotics: Cloud-based fleet management, analytics, and simulation services grow.

Sustainability focus: Energy-efficient robots and circular economy servicing models gain attention.

Future Outlook

Through 2035, the industrial robotics market will evolve from discrete automation islands into integrated, software-driven ecosystems. Expect a more diverse buyer base (SMBs to hyperscalers in warehousing), broader use-cases (e.g., precision assembly in electronics, automated lab workflows), and business models that emphasize outcome-based contracts and subscription revenue. Interoperability, open standards, and an ecosystem of software and service partners will determine winners.

Key Market Study Points

Total addressable market (TAM) dynamics: Growth driven both by unit deployments and rising per-system value from AI and software.

Adoption curve by vertical: Automotive remains core, while logistics, electronics and pharma show fastest near-term growth.

Service revenue potential: Aftermarket services (predictive maintenance, software updates) represent important recurring revenue.

Channel strategies: Direct OEM sales vs system integrators vs RaaS providers — each requires different go-to-market approaches.

Technology investment priorities: Vision systems, AI, human-robot safety systems, and cloud connectors.

Competitive Landscape

The market comprises robot OEMs, component suppliers (motors, controllers, sensors), system integrators, software/analytics vendors and emerging RaaS players. Competition focuses on:

Product breadth & reliability (industrial-grade arms vs collaborative robots).

Software & ecosystem (programming environments, simulation, fleet management).

Service footprint (global installation, local support).

Pricing & financing models (leasing, subscription/RaaS).

Key strategies companies pursue include expanding service offerings, acquiring integrators or software firms, and partnering with cloud and AI companies to offer differentiated, data-driven solutions.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=3187<ype=S

Recent Developments (directional themes)

Wider RaaS deployments enabling smaller firms to trial automation with lower upfront costs.

Commercial rollouts of AI-enabled inspection systems that replace manual quality control steps.

Increased collaboration between robotics and cloud/edge vendors to enable real-time orchestration.

Growth in specialized robotic end-effector start-ups (grippers, vision, force-sensing) providing rapid customization for niche tasks.

Stronger focus on cybersecurity standards for industrial control and robotic APIs.

Explore Latest Research Reports by Transparency Market Research:

Warehouse Automation Solutions Market - https://www.transparencymarketresearch.com/warehouse-automation-solutions-market.html

Warehouse Robotics Market - https://www.transparencymarketresearch.com/warehouse-robotics-market.html

Smart Power Distribution Systems Market – https://www.transparencymarketresearch.com/smart-power-distribution-systems-market.html

Artificial Intelligence Chipset Market - https://www.transparencymarketresearch.com/artificial-intelligence-chipsets-market.html

Microcontrollers Market - https://www.transparencymarketresearch.com/microcontrollers-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

Atil Chaudhari

Transparency Market Research Inc.

+1 518-618-1030

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.